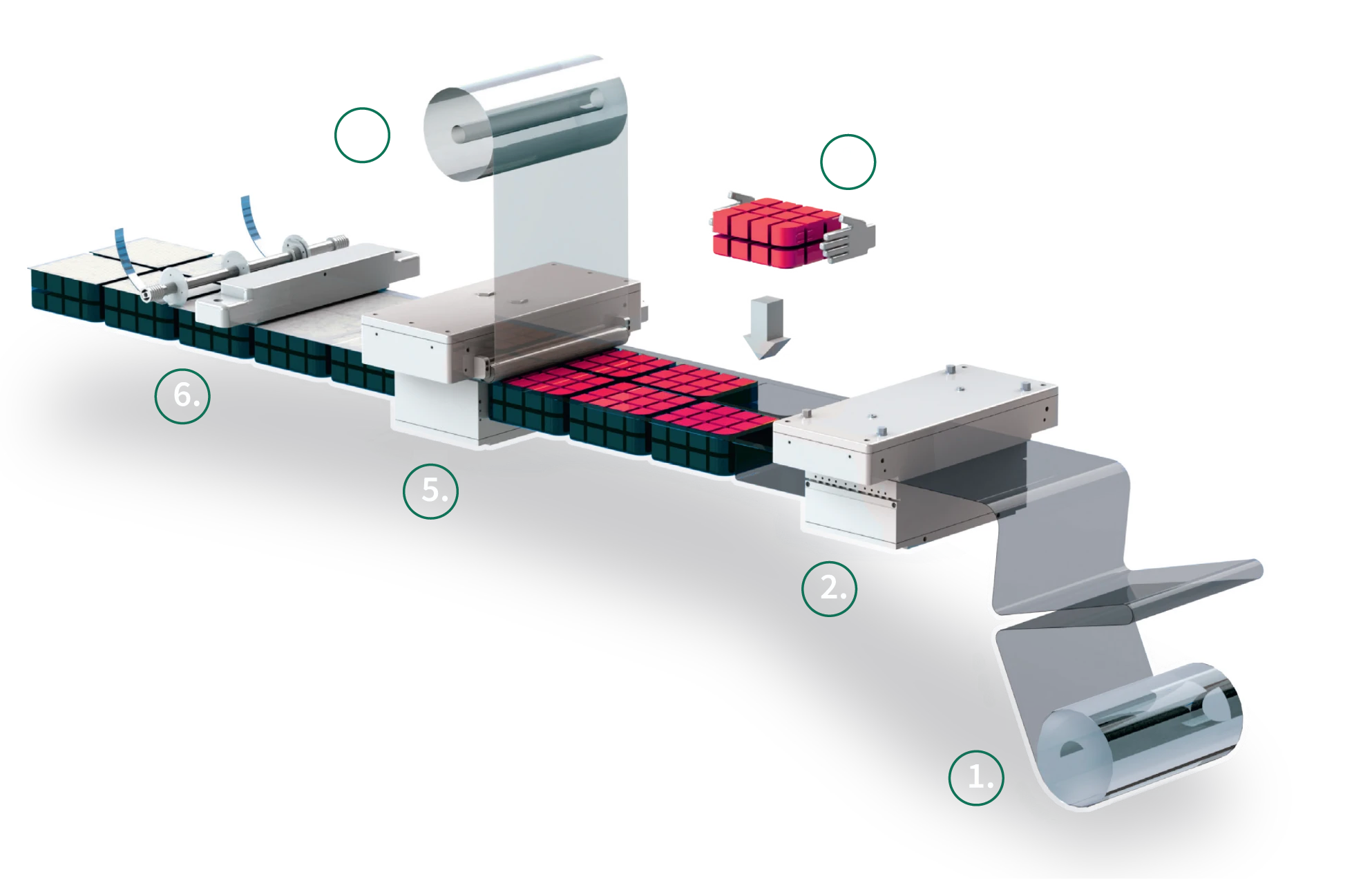

Thermoforming is a production process in which forming of a package, loading of a product into formed packages and sealing packages with the product are combined in a single production cycle.

Film used as packaging material is heated to required temperature and the package is shaped by air and vacuum in a special mould, which gives the package desired shape.

Thermoforming machine can be synchronized with additional equipment such as labelling system, slicer, dosing unit, multi-head weigher, printer or other compatible systems — creating a fully integrated and efficient packaging line.

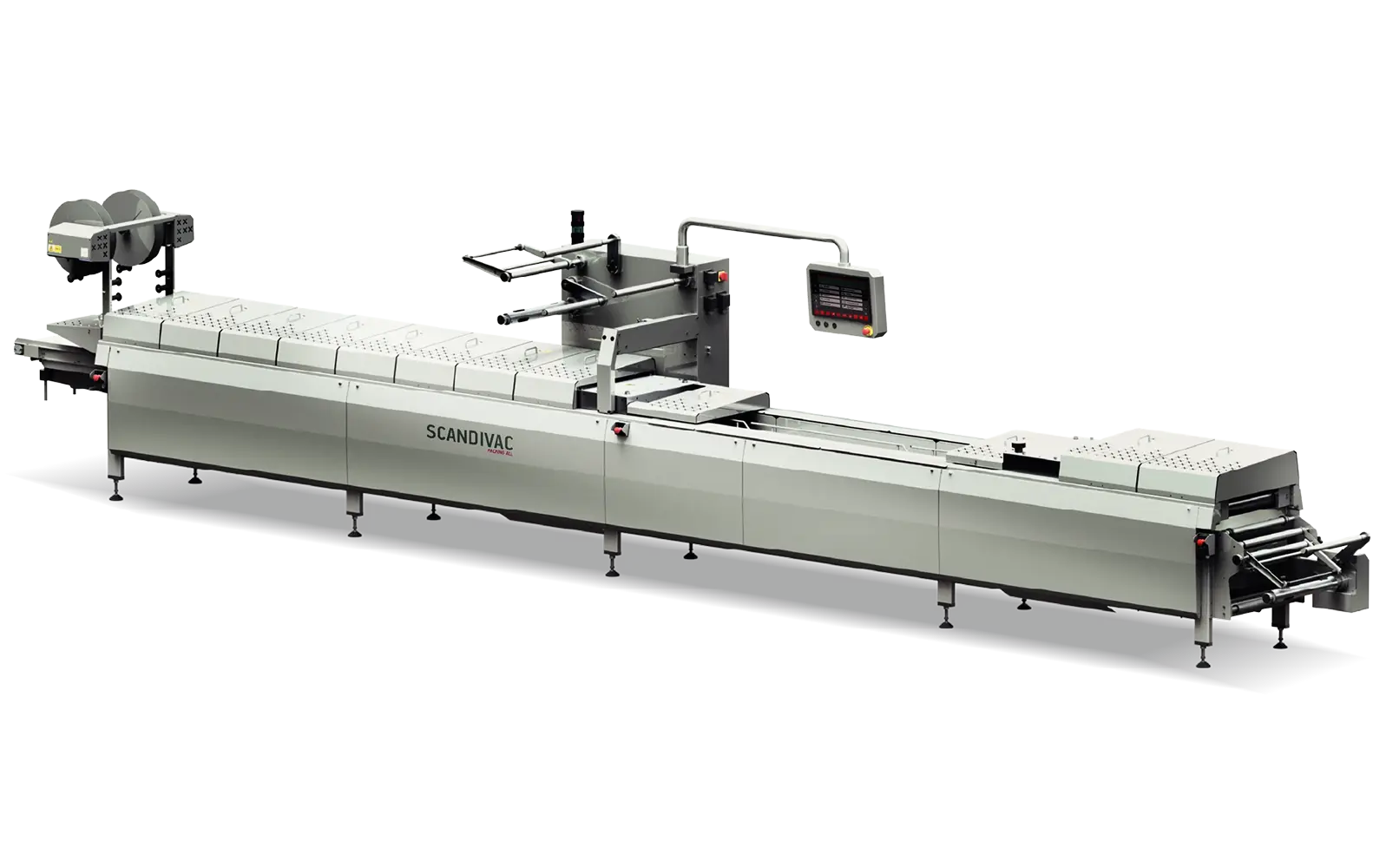

SC140

SC140

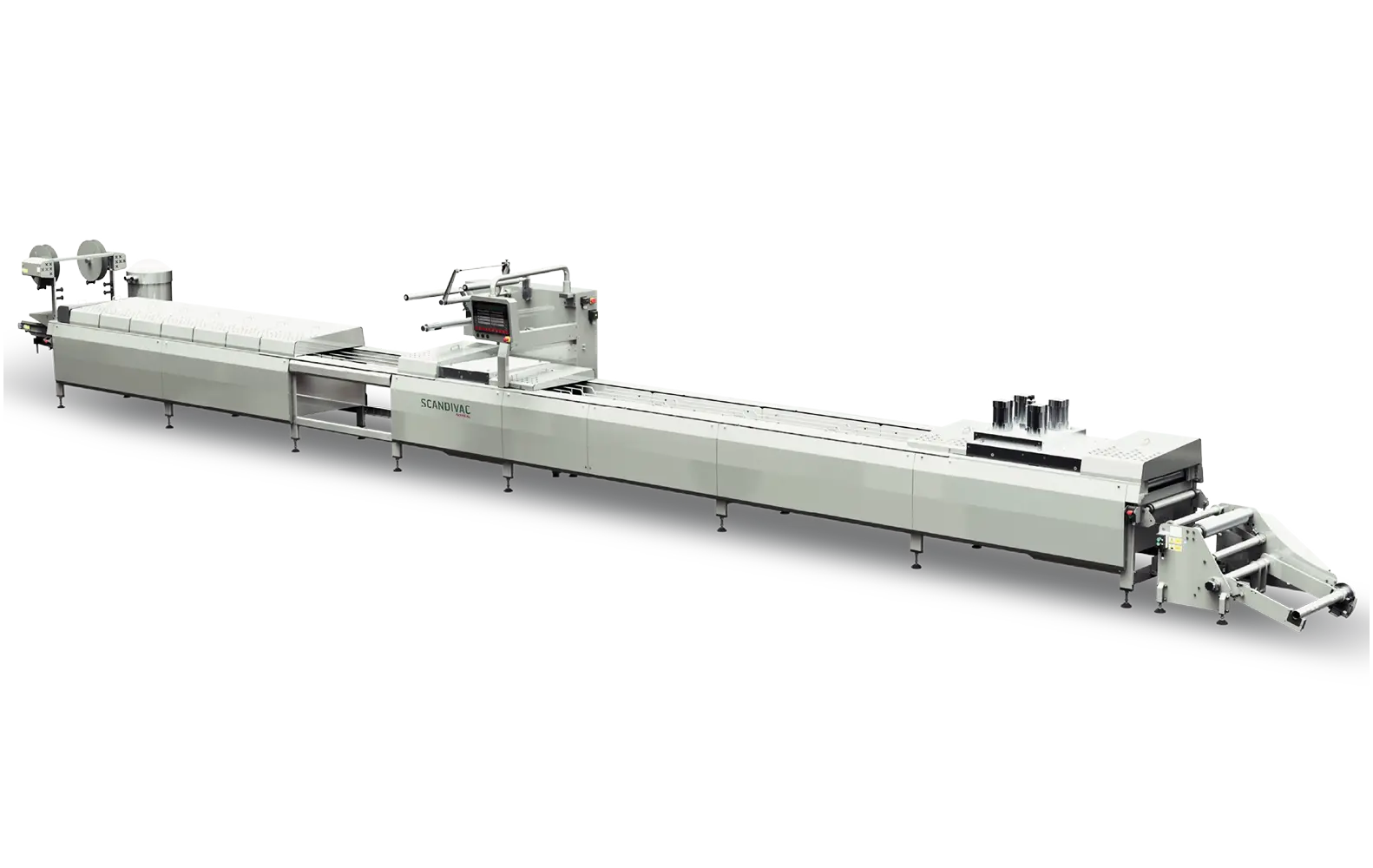

SC190

SC190

SC240

SC240

SC330

SC330