SC200TA

For increased production

CAPACITY

DIAMETER

CONTROL

with single station

with double stations

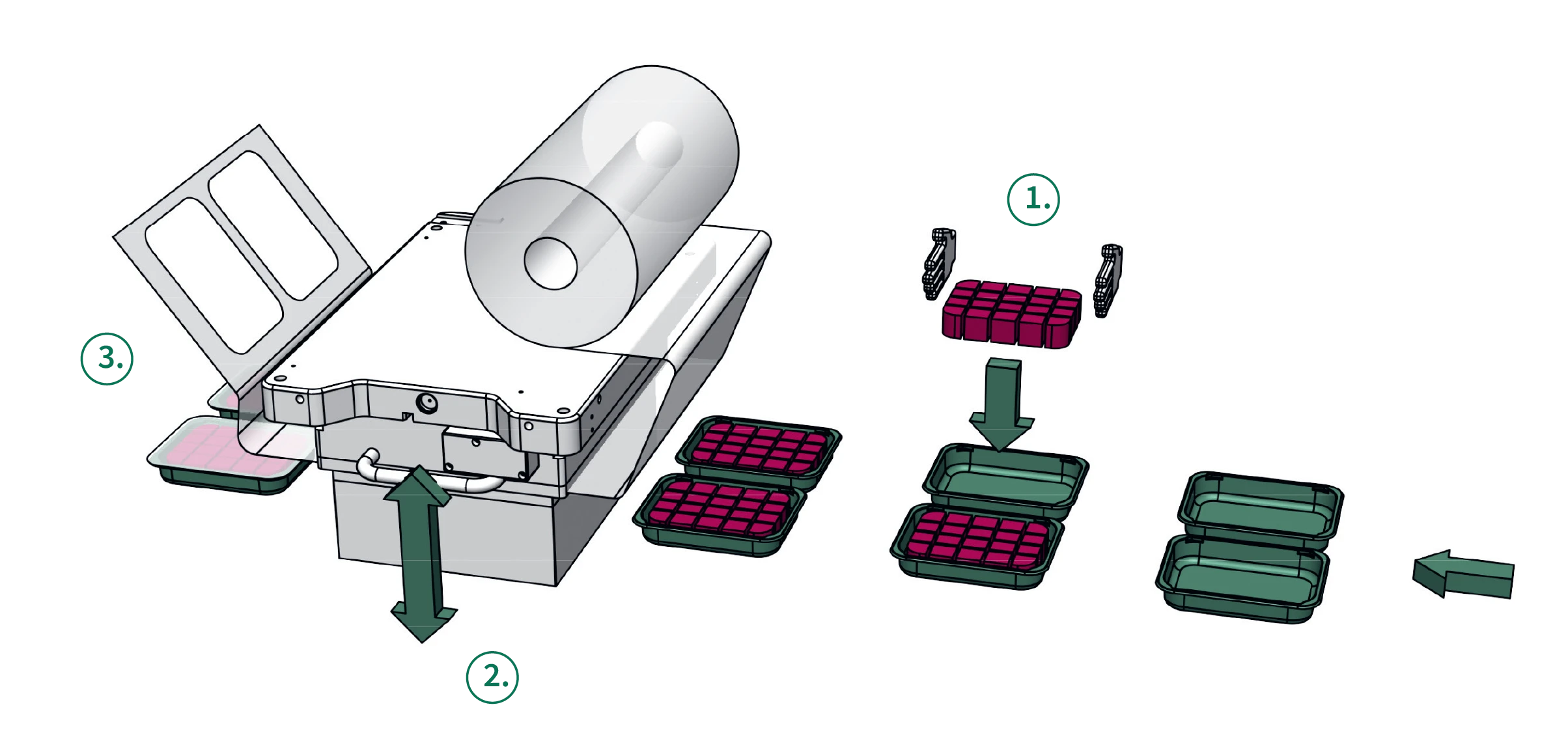

SC200TA machine is intended to reach higher production speed and consequently leads to higher packaging capacities. Its flexible tooling system allows for the die to be configured as a 1-track, 2-track or up to a 3-track setup, depending on tray size and production requirements. This versatility makes it an excellent choice for medium to large-scale businesses aiming to boost efficiency without compromising quality. Machine with single or double stations available.

SEALING

SEALING

VACUUM

VACUUM

MAP

MAP

SKIN without protrusion

SKIN without protrusion

SKIN protruding

SKIN protruding

Flat board SKIN protruding

Flat board SKIN protruding

Automatic traysealing is a production process in which a product is loaded into a preformed tray, which is then transported by chain conveyor and sealed with top film — all within a single, continuous production cycle.

Specification

- Photo cell for printed film

- Liquid separator in the vacuum line

- Particle filter for vacuum pump

- MAP with O2>21% (oxygen safe vacuum pumps)

- Integrated gas flash system for two different gas mixtures for easy approaching and selection from HMI

- Outfeed belt conveyor

- Synchronisation with additional equipment: automatic tray denester, dosing system, printer, labelling system, etc.

- Autonomous water cooling

- Trolley for tools replacement and storage

-

Machine weight 850 kg / 1340* kg

-

Machine dimensions2055 x 1122 x 1790 mm

3400 x 1122 x 1790* mm -

Electrical parameters400V-3P-50Hz, 220V-3P-60Hz

-

Compressed air6 - 7 bar

-

Protective gas2 - 6 bar

with double stations

-

Tray depthup to 90 mm

-

Tray depth for SKINup to 30 mm

-

Product height for SKIN

without protrudingup to 25 mm -

Product height for SKIN

with protrudingup to 50 mm -

Product protrusionup to 30 mm